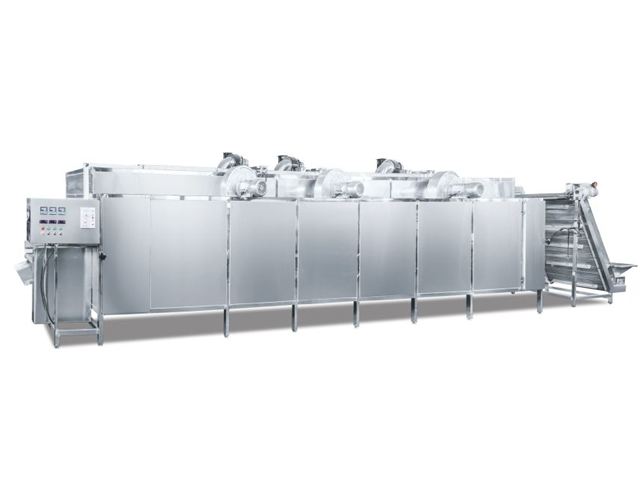

The fully automatic ready - to - eat vegetable processing production line and ready - to - eat vegetable processing equipment independently developed and produced by our company are essential fruit and vegetable processing machinery for ready - to - eat vegetable processing and distribution centers and quick - frozen fruit and vegetable processing manufacturers. They can be used for processing high - quality ready - to - eat vegetables, freshly cut vegetables, ready - to - eat vegetables, and pre - prepared vegetables. The products can be directly supplied to supermarkets, convenience stores, canteens, restaurants, and catering enterprises at all levels.

The root vegetable ready - to - eat vegetable processing production line can be used for processing high - quality ready - to - eat vegetables, freshly cut vegetables, ready - to - eat vegetables, and pre - prepared vegetables. It is suitable for root fruits and vegetables (such as cucumber slices, lettuce strips, carrot cubes, etc.), cut leafy vegetables (such as shredded lettuce, cabbage chunks, spinach segments, etc.), and cut fruit - type vegetables (such as green and red pepper strips, etc.).

First, the root vegetables are peeled and cleaned by a bristle roller peeling and cleaning machine. Then, they are transported by a lifting conveyor belt to a workstation sorting table with an intermediate conveyor belt. Workers will remove the spoiled parts and trim the vegetables manually. After that, the root vegetables are thrown into a vegetable cutter for cutting. The diced, shredded, or sliced vegetables coming out of the vegetable cutter directly fall onto the conveyor belt and are transported by the conveyor belt to a high - position vortex cleaning machine. Ozone sterilization is carried out in the first set of high - position vortex cleaning machines. Then, the vegetables go through a second set of vortex cleaning machines for another round of cleaning. During this process, the smell of ozone is reduced, and the ozone on the vegetable surface is diluted. After cleaning, the vegetables are dehydrated, and the dehydration method can be freely selected according to product requirements.