产品中心

联系我们

Zhucheng Muchang Food Machinery Co., Ltd.

Contact: Manager Ge

Contact number: +8615206982955

Address: Zhucheng Economic Development Zone

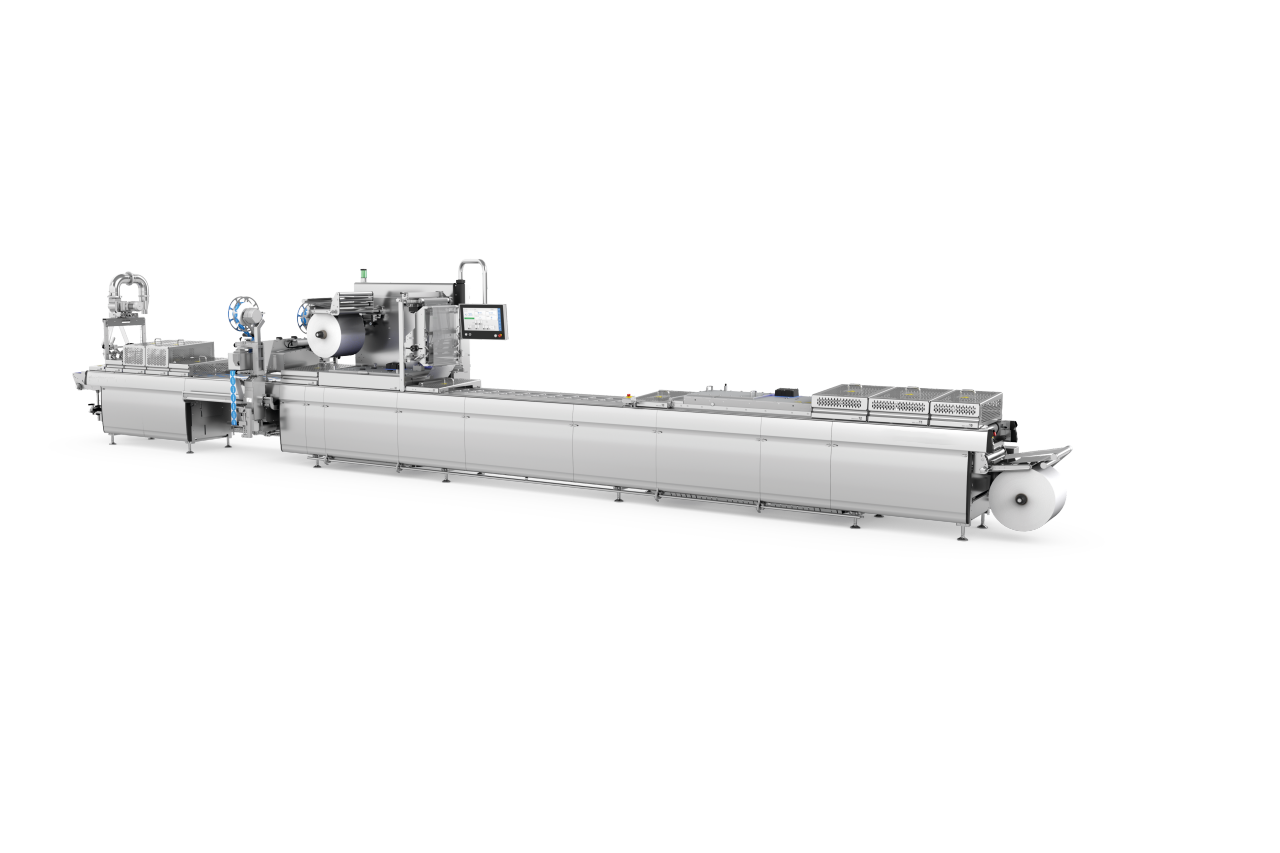

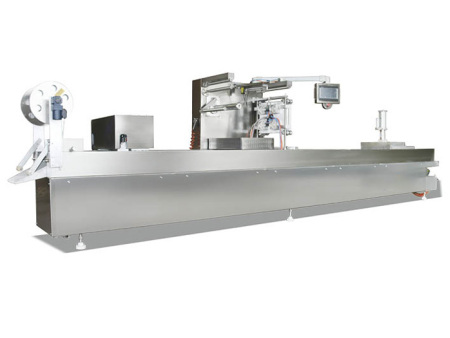

Packaging line 620

更新时间:2024-12-10

Product Introduction

Main Technical Parameters: Model 620 Fully Automatic Stretch Vacuum Packaging Machine

Main Features

相关推荐

Contact us

Contact: Manager Ge

Contact number: +8615206982955

Address: Zhucheng Economic Development Zone